Sunbeam Microwave User Manual: A Comprehensive Guide

Welcome! This manual provides essential guidance for your Sunbeam microwave, offering over a century of convenient solutions for daily life and optimal performance.

Congratulations on selecting a Sunbeam microwave! For over 100 years, Sunbeam has been dedicated to providing innovative and convenient solutions to enhance your everyday life. Your new microwave is designed for both versatility and ease of use, offering a range of features to simplify your cooking tasks.

Before you begin, please take a few moments to read this user manual thoroughly. It contains important information regarding safety precautions, operating instructions, and maintenance guidelines. Familiarizing yourself with these details will ensure optimal performance and longevity of your appliance.

This manual will guide you through identifying your specific Sunbeam microwave model, understanding its various components, and utilizing its full potential. We are confident that your Sunbeam microwave will become an indispensable part of your kitchen.

Understanding Microwave Safety

Your safety is paramount when operating a microwave oven. Always ensure the appliance is properly grounded and avoid operating it with a damaged cord or plug. Never attempt to repair the microwave yourself; contact qualified service personnel for assistance.

Do not heat sealed containers or eggs in their shells, as they may explode. Use microwave-safe cookware and avoid metal objects, which can cause sparks and fire. Be cautious when heating liquids, as they can become superheated and erupt violently.

Regularly inspect the door seals and the interior for damage. Do not operate the microwave if the door does not close securely. Keep the area around the microwave clear to ensure adequate ventilation. Supervise children when they are near the appliance.

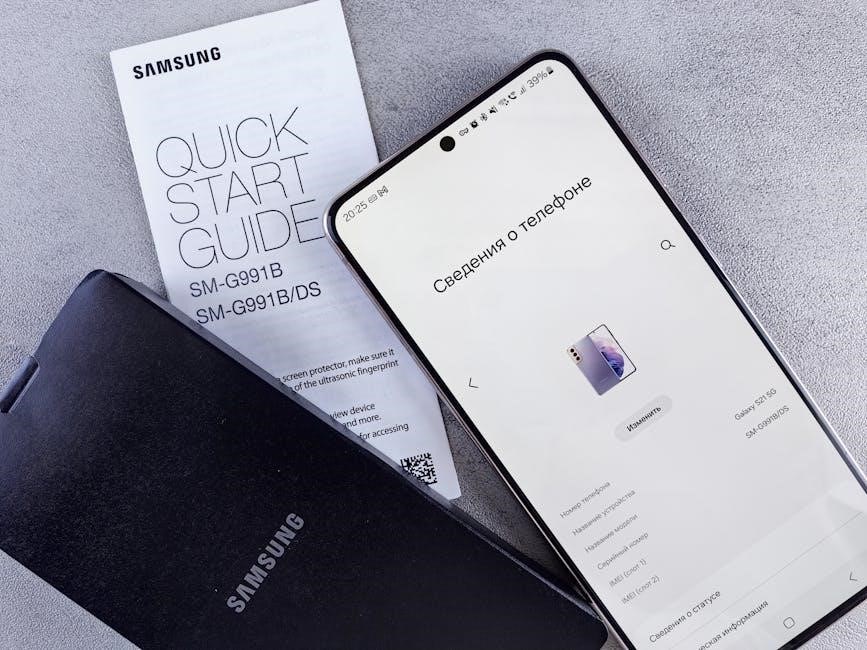

Locating Your Sunbeam Microwave Model Number

Finding your Sunbeam microwave’s model number is crucial for accessing specific support, manuals, and replacement parts. This unique identifier helps ensure you receive the correct information for your particular appliance.

Typically, the model number is located on a sticker or metal plate affixed to the appliance. Common locations include the back panel, the bottom surface, or the interior frame – often near the door opening or inside the cavity itself.

Carefully inspect these areas; the model number is usually embedded within a larger string of characters. Note it down as it will be required when contacting customer service or ordering parts. Having this information readily available streamlines the support process.

Important Safety Instructions

Your safety is paramount when using this Sunbeam microwave. Always ensure the appliance is properly grounded. Never operate the microwave if the door doesn’t close securely or if the seals are damaged. Avoid heating sealed containers, as they may explode.

Do not use the microwave for drying clothes or other non-food items. Supervise children when they are near the appliance. Regularly inspect the power cord for damage, and discontinue use if any damage is found.

Never attempt to repair the microwave yourself; contact qualified service personnel for any repairs. Avoid operating the microwave empty, as this can damage the magnetron. Follow all instructions carefully to prevent fire, electrical shock, or injury;

Microwave Features and Components

Explore your Sunbeam! This section details the control panel, interior cavity with the turntable, and the crucial waveguide cover for efficient operation.

Control Panel Overview

Navigating the Controls: Your Sunbeam microwave’s control panel is designed for intuitive operation. Familiarize yourself with the numbered keypad for direct time entry, and the “Start” button to initiate cooking cycles. The “Stop/Clear” button halts operation and resets settings.

Power Levels & Pre-sets: Utilize the “Power Level” button to adjust cooking intensity, ranging from defrost to high power. Explore the pre-set cooking programs for convenient options like popcorn, potato, or reheat. These programs automatically adjust time and power for optimal results.

Timer & Clock: The control panel also features a clock for timekeeping and a timer function for non-microwave tasks. Refer to the detailed diagrams within this manual to pinpoint each button’s specific function and ensure a seamless cooking experience with your Sunbeam appliance.

Interior Cavity and Turntable

Optimizing Cooking Performance: The Sunbeam microwave’s interior cavity is engineered to distribute microwaves evenly for consistent cooking results. The smooth walls facilitate microwave reflection, minimizing hotspots and ensuring food is heated thoroughly.

Turntable Functionality: The rotating glass turntable is a crucial component, constantly moving food through the microwave energy for uniform heating. Ensure the turntable and its supporting roller ring are always clean and properly positioned for optimal performance.

Safe Food Practices: Never operate the microwave without the turntable in place. Avoid placing oversized dishes that obstruct rotation. Regularly inspect the turntable for cracks or damage, replacing it if necessary to maintain safe and efficient operation within your Sunbeam microwave;

Waveguide Cover

Protecting Your Microwave: The waveguide cover, typically made of mica, is a vital component located inside the microwave cavity. Its primary function is to protect the waveguide – the channel that directs microwaves into the cooking area – from food splatters and residue.

Maintaining Performance: A clean waveguide cover is essential for efficient microwave operation. Food buildup can absorb microwaves, reducing heating performance and potentially causing arcing or damage. Regularly inspect the cover for grease or food particles.

Cleaning & Replacement: Gently clean the cover with a damp cloth and mild detergent. Never operate the microwave if the waveguide cover is damaged or missing; replace it immediately to prevent internal damage and ensure continued safe operation of your Sunbeam microwave.

Operating Your Sunbeam Microwave

Get Started: Easily set cooking times, power levels, and utilize pre-set programs for convenient operation, alongside effective defrosting features for your Sunbeam appliance.

Setting the Cooking Time

Precise Control: To set the desired cooking time on your Sunbeam microwave, begin by pressing the ‘Time Cook’ or similar button on the control panel. The display will illuminate, prompting you to enter the cooking duration. Utilize the number pad to input the minutes and seconds – for example, ‘1’ then ‘0’ for one minute, or ‘1’ ‘0’ ‘3’ ‘0’ for one minute and thirty seconds.

Start Cooking: Once the time is entered, press the ‘Start’ button to initiate the cooking process. The microwave will operate for the specified duration. You can monitor the remaining time on the display. To pause the cooking mid-cycle, simply press the ‘Stop/Clear’ button. To resume, re-press ‘Start’. Remember to always check food doneness after the timer reaches zero, as cooking times may vary based on food type and quantity.

Adjustments: If you need to add more time during cooking, press the ‘Time Cook’ button again and enter the additional seconds or minutes, then press ‘Start’.

Power Level Selection

Controlling the Heat: Your Sunbeam microwave offers adjustable power levels to suit various cooking needs. After entering the cooking time, or sometimes before, locate the ‘Power Level’ button on the control panel. Pressing this button repeatedly cycles through the available power settings, typically ranging from 10% to 100% in increments.

Understanding the Levels: 100% power is ideal for rapid cooking, boiling, and reheating. Lower power levels (50% or 70%) are best for delicate tasks like defrosting, simmering, or softening butter, preventing splattering and uneven cooking. For very gentle heating, use 30% or lower. The display will indicate the selected power level.

Optimal Results: Experiment with different power levels to achieve the best results for your recipes. Refer to your recipe or food packaging for recommended power settings. Always start with a lower power level and increase if needed.

Using Pre-set Cooking Programs

Convenience at Your Fingertips: Many Sunbeam microwaves feature pre-set cooking programs designed for common foods like popcorn, potatoes, pizza, and frozen vegetables. These programs automatically set the appropriate cooking time and power level for optimal results, simplifying your cooking process.

Accessing the Programs: To use a pre-set program, simply press the corresponding button on the control panel – for example, ‘Popcorn’ or ‘Pizza’. The microwave will then initiate the pre-programmed settings. Some models may require you to enter the food’s weight or quantity after selecting the program.

Customization Options: While convenient, pre-set programs can sometimes be adjusted. Check your model’s specific instructions to see if you can modify the cooking time or power level within a program. Always monitor the food during cooking to ensure it’s heated to your liking.

Defrosting with Your Sunbeam Microwave

Quick and Efficient Defrosting: Your Sunbeam microwave offers a convenient defrost function for thawing frozen foods quickly and evenly. This feature utilizes low power levels to prevent cooking during the thawing process, preserving the food’s texture and flavor.

Weight or Time Defrost: Most models offer two defrosting options: by weight or by time. For weight defrost, enter the weight of the frozen food, and the microwave will automatically calculate the defrosting time. For time defrost, manually set the desired defrosting duration.

Important Considerations: It’s crucial to rotate or flip the food halfway through the defrosting cycle to ensure even thawing. Always remove any packaging before defrosting, and consume defrosted food immediately for optimal safety and quality.

Care and Maintenance

Maintaining Your Microwave: Regular cleaning ensures optimal performance and longevity of your Sunbeam microwave, keeping it hygienic and efficient for years to come.

Cleaning the Interior

Keeping it Fresh: To clean the interior of your Sunbeam microwave, begin by unplugging it from the power outlet for safety. Then, carefully remove the turntable and roller ring, washing them separately with warm, soapy water. For stubborn food splatters inside the microwave cavity, a simple solution of water and lemon juice can be incredibly effective.

Place the mixture in a microwave-safe bowl and heat on high for several minutes, allowing the steam to loosen the debris. Afterwards, wipe down the interior surfaces with a soft cloth or sponge; Avoid using abrasive cleaners or scouring pads, as these can damage the microwave’s interior lining. Pay close attention to the waveguide cover, ensuring it remains clean and free of residue. Finally, dry the interior thoroughly before replacing the turntable and roller ring, and plugging the microwave back in.

Cleaning the Exterior

Maintaining the Shine: Cleaning the exterior of your Sunbeam microwave is straightforward. Always begin by disconnecting the appliance from the power source to prevent any electrical hazards. Use a soft, damp cloth with a mild detergent solution to wipe down the exterior surfaces. Avoid harsh chemicals, abrasive cleaners, or scouring pads, as these can damage the finish.

For stainless steel models, a stainless steel cleaner can be used to maintain its luster. Pay particular attention to the control panel, ensuring that any spills or splatters are promptly cleaned to prevent them from becoming sticky or difficult to remove. After cleaning, wipe the exterior dry with a clean, soft cloth. Regular cleaning will help keep your Sunbeam microwave looking its best and functioning optimally for years to come.

Turntable and Roller Ring Maintenance

Ensuring Smooth Rotation: Proper maintenance of the turntable and roller ring is crucial for even cooking. Regularly remove the turntable and roller ring from the microwave interior. Wash them in warm, soapy water, or place them in the dishwasher if they are dishwasher-safe – check your model’s specific instructions.

Inspect the roller ring for any cracks or damage. If damaged, replace it to ensure the turntable rotates smoothly. Ensure the roller ring is properly seated when reassembling. Wipe down the cavity beneath the roller ring to remove any food debris or spills that may have accumulated. A clean roller ring and turntable contribute to efficient microwave operation and prevent unwanted noises during use.

Troubleshooting Common Issues

Facing problems? This section addresses frequent concerns like heating failures, turntable malfunctions, and unusual noises, offering solutions for a seamless experience.

Microwave Not Heating

Problem: Your Sunbeam microwave appears to be running – the light is on, the turntable rotates, and the timer counts down – but food isn’t heating. Several factors could contribute to this issue. First, verify the power cord is securely plugged into a functioning outlet. Test the outlet with another appliance to confirm it’s delivering power.

Next, ensure the door is closing properly. The microwave won’t operate if the door isn’t fully latched, activating the safety interlock switches. Inspect the door for any obstructions or damage preventing a tight seal. Also, check the power level setting; it might be set too low. Confirm you haven’t accidentally selected a ‘Defrost’ or ‘Warm’ setting instead of a cooking function.

If these checks don’t resolve the issue, there might be a problem with the magnetron, the component responsible for generating microwaves. Do not attempt to repair this yourself; it requires specialized knowledge and can be dangerous. Contact Sunbeam Consumer Services for assistance or a qualified appliance repair technician.

Turntable Not Rotating

Problem: The turntable inside your Sunbeam microwave isn’t rotating during operation, potentially leading to unevenly heated food. First, ensure the turntable and roller ring are correctly positioned. Remove both, clean them thoroughly, and then reassemble, making sure the roller ring’s pegs align with the slots in the microwave’s base.

Check for obstructions beneath the turntable. Food particles or spills can prevent smooth rotation. Also, verify the turntable isn’t overloaded; excessive weight can strain the motor. If the turntable still doesn’t rotate, inspect the roller ring for damage – cracks or breaks can hinder its function.

A faulty turntable motor could also be the cause. However, do not attempt to disassemble or repair the microwave yourself. Contact Sunbeam Consumer Services or a qualified appliance technician for diagnosis and repair. Ignoring this issue can lead to further damage or inconsistent cooking results.

Strange Noises During Operation

Hearing unusual sounds from your Sunbeam microwave during operation can be concerning. A buzzing noise often indicates arcing, potentially caused by metal objects inside or damage to the waveguide cover. Immediately stop the microwave and remove any metallic items. Inspect the waveguide cover for burns or damage – do not use if compromised.

Rumbling or grinding sounds might suggest a problem with the turntable motor or the cooling fan. Ensure the turntable is properly seated and free of obstructions; If the noise persists, or if you hear a loud clicking sound, discontinue use.

Never attempt to self-repair the microwave. Contact Sunbeam Consumer Services or a qualified technician for assistance. Ignoring strange noises could lead to more significant damage or pose a safety hazard. Always prioritize safety and professional repair for internal microwave components.

Warranty Information

Sunbeam Products, Inc., located in Boca Raton, Florida, offers a warranty within the U.S.A. Contact Consumer Services for details and claims.

Sunbeam Warranty Details (U.S.A.)

Sunbeam Products, Inc., extends a limited warranty to purchasers within the United States. This warranty covers defects in materials and workmanship under normal household use, beginning from the date of original purchase. The duration of the warranty varies depending on the specific Sunbeam microwave model; please retain your proof of purchase to determine your coverage period.

This warranty does not cover damage resulting from misuse, abuse, accidents, unauthorized repairs, or alterations. It also excludes components subject to normal wear and tear. To obtain warranty service, contact Sunbeam’s Consumer Services Department. You may be required to return the defective product for inspection or replacement. Sunbeam reserves the right to repair or replace the product at its discretion.

This warranty provides you with specific legal rights, and you may have other rights which vary from state to state. For complete warranty terms and conditions, please visit the Sunbeam website or contact Consumer Services directly. Remember to register your product for faster service!

Contacting Consumer Services

Need assistance with your Sunbeam microwave? Our dedicated Consumer Services Department is here to help! For any questions, concerns, or warranty claims related to your appliance, please don’t hesitate to reach out. Sunbeam Products, Inc. is located in Boca Raton, Florida 33431, and our team is committed to providing excellent support.

You can contact us through several convenient channels. Visit the official Sunbeam website for a comprehensive FAQ section and online support resources. Alternatively, you can reach our team via phone during regular business hours. Please have your model number and proof of purchase readily available when contacting us, as this will expedite the assistance process.

We strive to resolve your issues quickly and efficiently. Our representatives are knowledgeable and eager to ensure your satisfaction with your Sunbeam microwave. Don’t hesitate to connect – we’re here for you!

Finding Replacement Parts

Locate Sunbeam microwave parts easily! Explore eReplacement Parts, Goodmans, Marbeck, Seneca River Trading, and Turnpike Appliance Service for various components.

Sunbeam eReplacement Parts

Sunbeam’s eReplacement Parts website is a dedicated resource for sourcing genuine replacement components for your microwave and other Sunbeam appliances. This platform allows you to directly search for parts based on your specific model number, ensuring compatibility and a proper fit.

You can select from 26 different Sunbeam models, accessing parts lists, owner’s manuals, and detailed diagrams to aid in identification and installation. Popular models like the SBM7500W are featured, with over 51 available parts, including motors and blades.

This online store simplifies the process of repairing your Sunbeam microwave, offering a convenient alternative to contacting customer service or visiting physical stores. By utilizing eReplacement Parts, you can extend the lifespan of your appliance and avoid unnecessary replacements, saving both time and money.

Popular Sunbeam Microwave Models & Parts

Sunbeam offers a diverse range of microwave models, catering to various needs and preferences. Among the popular choices is the Model SBM7500W, a frequently sought-after unit with readily available replacement parts. Finding the correct parts for your specific Sunbeam microwave is streamlined through dedicated resources.

For the SBM7500W, over 51 parts are currently available, encompassing essential components like motors, blades, and various internal mechanisms. Accessing these parts often involves utilizing the Sunbeam eReplacement Parts website, where detailed diagrams and model-specific lists are provided.

Understanding your microwave’s model number is crucial for accurate part identification. These numbers are typically located on the back, bottom, or body of the appliance, often on a sticker or metal plate. Utilizing this information ensures you order the correct components for a successful repair.

Where to Purchase Sunbeam Parts

Sunbeam parts can be conveniently purchased through several channels, ensuring accessibility for repairs and maintenance. The primary resource is the official Sunbeam home eReplacement Parts website, offering a comprehensive catalog tailored to various models. This platform allows direct selection from 26 different models, simplifying the search process.

Beyond the official website, several authorized retailers and service providers stock Sunbeam microwave parts. Goodmans Sales Service, Marbeck Appliance Parts, Seneca River Trading, Inc., and Turnpike Appliance Service are listed as potential sources. These options provide alternatives for those preferring local purchasing or specialized assistance;

Additionally, Sunbeam products, including irons and microwaves, are widely distributed through mass merchants and department stores, offering another avenue for acquiring replacement parts. Remember to have your model number handy for a smooth and accurate purchase experience.